Dewatering

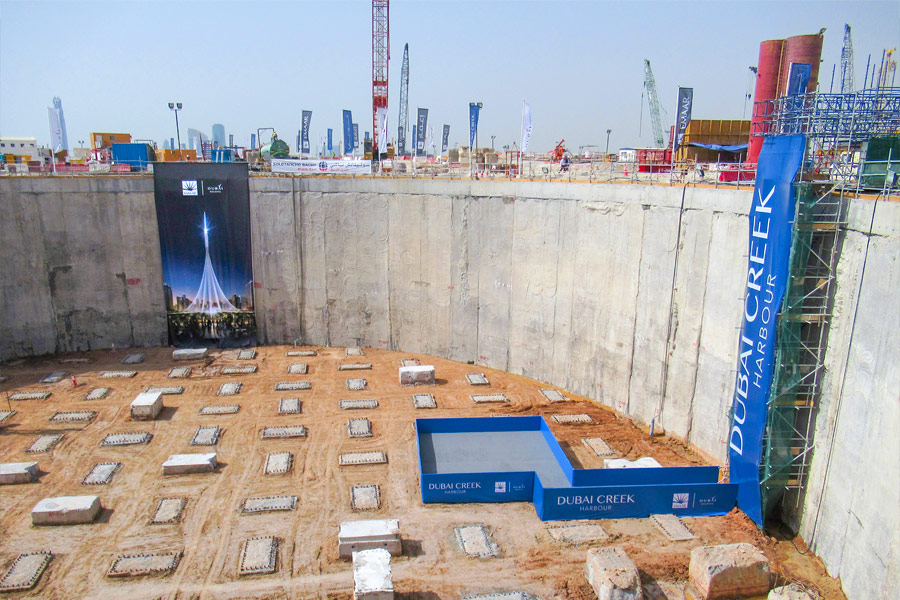

Dewatering systems are routinely used to provide temporary reductions in ground water levels for structures which extend to below the groundwater level. Dewatering systems may be used around open cut excavations or in conjunction with shoring or retaining walls.

Hydroserv specializes in the design, installation and management of wellpoint dewatering, deep well dewatering and sump pump dewatering.

Water Treatment & Remediation

Contamination of groundwater and treatment for removal of hazardous substances to meet discharge limits is integral to our core business to prevent significant negative effects to our natural environment. We have a range of services, skills and technologies to provide the correct solution for your contamination problems and ensuring environmental security.

Our capabilities include treatment systems for turbid water, hydrocarbon contamination, SVE remediation, filtration and many more solutions either at full turnkey scale or pilot and trial testing. Data collection, monitoring, testing, analysis and reporting is part of the service we provide along with prior experience on remediation projects all over Europe, the Middle East and Australasia.

Over Pumping, Sewerage Works & Emergency Pumping

Whether your works are a planned bypass project or an emergency response requirement, Hydroserv has a broad selection of pumps that can handle any flow requirement.

We can respond to any level of emergency and will have your emergency situation under control and giving you peace of mind. We have been directly involved with sewer malfunctions, severe rain events and drainage infrastructure failures. We have experienced personnel ready for dispatch to handle any emergency. Our emergency contact number is 24/7 and we are available at immediate notice to mobilise and provide reliable solutions, services and equipment.

Our emergency contact numbers are:

Doha, Qatar: +974 3063 1342

Sultanate of Oman: +968 9648 7013

United Arab Emirates: +974 3063 1342

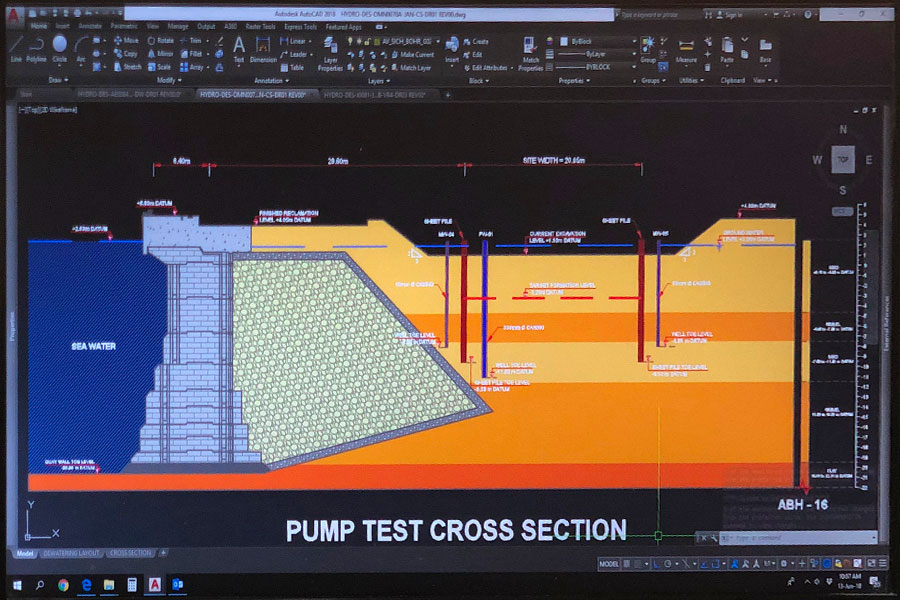

Pumping Tests

A pump test can provide valuable information for the planning and design of construction projects. The test involves pumping from a test well at a controlled rate and monitoring the flow rate from the well and the drawdown in an array of observation wells at varying radial distances from the test well. A pump test is typically carried out to assess the permeability values for groundwater management and design purposes. Hydroserv can plan and design a pump test for your requirements and model and analyse the resultant data to provide accurate information on your project pumping needs.

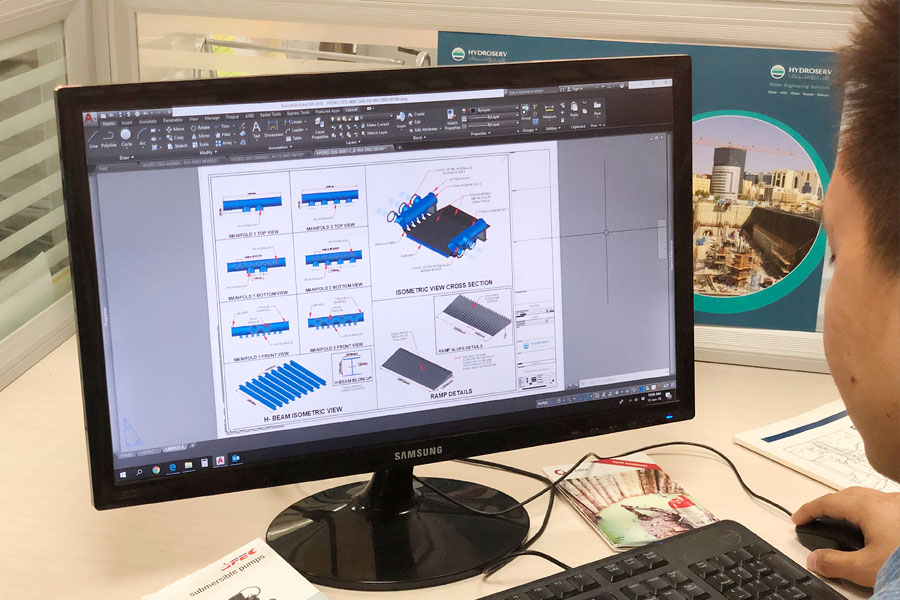

Modelling

Hydroserv can offer modelling services for dewatering related activities and groundwater contamination design and particle tracking. 2D and 3D numerical modelling services operating in steady or transient states with a number of modelling packages are available. We also have the option to use special add-on packages for complicated boundary conditions or individual well modelling if required.

Our integrated modelling services are designed to provide analysis and design throughout the entire life cycle of a dewatering project form the site investigation stage, system design and operation up to the system shut down and recovery. The services extend further to groundwater build up review against the newly built structure. We also specialise in the analysis of dewatering system design in conjunction with groundwater cut-off structures such as diaphragm walls, secant piles, sheet piles, slurry walls, etc.

Pipe Laying

Hydroserv uses high-density polyethylene pipe (HDPE) pipework for all our pumping systems and dewatering installations. It is a cost effective solution for a broad range of piping requirements and is extremely durable, reliable and leak-resistant. It is easily installed by our trained and certified welders and can carry potable water, groundwater, wastewater, slurries, hazardous wastes and slurries. It will guarantee long service and trouble free installation.

Rentals

Hydroserv rent a wide range of materials and equipment in the dewatering, pumping fields and remediation fields. Our modern fleet of up to date, durable equipment and our sales and operations teams can assist in selecting the right technology to meet your project needs.

We stock a large fleet of the following pumps:

- Electric pumps from 3.6m3/hr to 350m3/hr and heads up to 450m

- High head diesel pumps from 40m3/hr to 2650m3/hr and heads up to 150m

- Low head diesel pumps from 200m3/hr to 1550m3/hr and heads up to 26m

Our pumps are known for their reliability and fuel efficiency, a key driver in pump selection.

- Drilling rigs with diameter 50mm to 1000mm and depths of up to 1500m

- Wheel washers, road sweepers and ramps for temporary project installations

- Wide range of water remediation plant including settling tanks, clarifiers, bacteria removal systems and hydrocarbon abatement systems

Water Jetting & Blasting

Skid or trailer mounted high pressure and ultra-high pressure pumps available as part of our services to our industrial customers. The pumps and waterblast systems, with fluid ends capable of pressures up to 40,000 PSI are available on a rental basis. Our range of pumps offer superior performance and quality and are easy and safe to handle. They can be used in a variety of applications including drain and sewer cleaning, pipe cleaning and heat exchanger tube cleaning. Our experienced team will ensure the right product is tailored to your application.

Drilling

Hydroserv own and operate a fleet of drilling rigs used for water supply, dewatering, earthing protection and monitoring applications. Drilling diameters are available from 100mm to 1000mm and depths of up to 1500m. Our machines are available for rent with experienced and competent drillers.

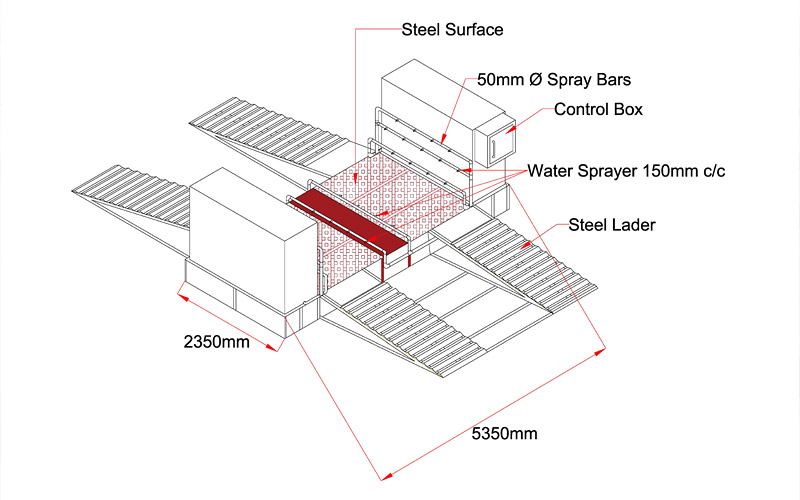

Pressure Washers & Wheel Washers

Hydroserv’s pressure washers and wheel wash systems are designed for industrial and construction applications. A full range of pressure washers is available for rental to assist in your site cleaning operations.

Our wheel washers can be delivered for either temporary or permanent installations and for a variety of vehicle sizes to control and manage sediment removal from sites.

Pipeline Flushing

To continue to operate at peak efficiency, process systems and pipelines must be kept as clean as possible. Some of the normal by-products of operating processes create deposits, ranging from scales to sludge, precipitates and even metal deposits. These types of build-up foul the piping and can significantly reduce system efficiency, eventually causing plugging and failure of the unit.

We will identify the key process equipment and solvents required for the cleaning process based on the type of pipeline or system material being used. Subsequently, we will generate the project work scope required to conduct the task, undertake system performance reviews and train personnel. Upon job completion, all solvents are carefully disposed of without causing any harm to the environment.

Hydroserv’s chemical cleaning process will reduce downtime, reduce exposure to toxic materials and environmental hazards.